Electric Vehicles (EVs) are no longer a niche category; they are becoming the backbone of the global automotive industry. With rapid adoption worldwide—led by China—a new demand has emerged: specialized EV tyres.

These tyres are engineered differently from conventional PCR (Passenger Car Radial) tyres, designed to handle EV-specific challenges such as higher torque, heavier battery weight, and the need to maximize driving range.

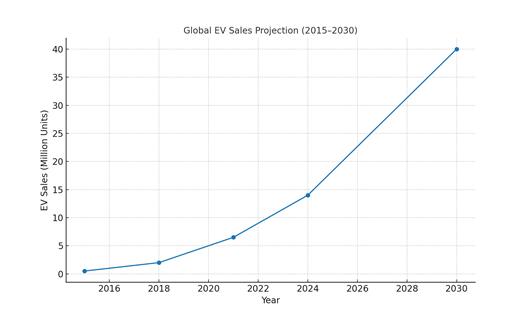

1. Global EV Adoption: A Market on the Rise

EV sales are accelerating worldwide. In 2024, global EV sales exceeded 14 million units, representing around 18% of all new car sales. By 2030, this figure is projected to surpass 40% of new car sales.

China remains the undisputed leader, accounting for more than 60% of global EV sales.

.

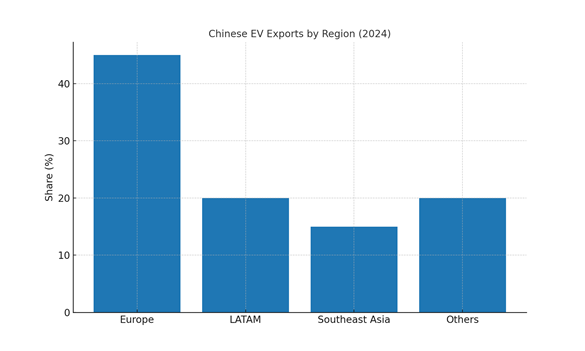

2. China’s EV Market Share Worldwide

China not only leads in EV adoption but also dominates EV exports. In 2024 alone, China exported more than 1.8 million EVs, expanding into Europe, Latin America, and Southeast Asia.

Global brands like BYD, SAIC, and NIO continue to expand aggressively, cementing China’s role as the hub of EV manufacturing.

3. Rising Demand for EV Tyres in China

Chinese tyre manufacturers are rapidly scaling up production of EV-specific tyres. Industry leaders such as Linglong, Sailun, and Giti Tire have already introduced dedicated EV product lines.

This demand is fueled not only by China’s domestic EV boom but also by its fast-growing export markets, where every exported EV requires tyres engineered to match its performance profile.

4. PCR vs. EV PCR Tires: Key Differences

EVs require specialized tires that can handle unique operating conditions. Below is a comparison of conventional PCR tires versus EV-specific PCR tires:

| Feature | Conventional PCR Tire | EV-Specific PCR Tire |

| Weight Load | Designed for lighter vehicles | Reinforced for heavier EV battery weight |

| Torque Resistance | Standard construction | Handles instant EV torque |

| Rolling Resistance | Moderate | Lower to extend range |

| Noise Reduction | Basic NVH control | Foam lining & design for quieter ride |

| Durability | Longer lifespan under normal load | Slightly reduced lifespan due to high stress |

| Cost | Generally lower | Higher due to advanced materials |

5. Real-World Impact

When EV-specific tyres are fitted on vehicles like the Tesla Model 3 or BYD Seal, drivers report:

- Extended driving range

- Reduced road noise

- Improved handling under torque

This proves EV tyres aren’t just a marketing claim — they are a necessity for both performance and efficiency.

6. Challenges & Future Outlook

While EV tyres deliver clear benefits, challenges remain:

- Higher costs due to advanced compounds

- Faster wear rates under high torque

- Recycling and retreading concerns

The future, however, is promising. Innovations already underway include:

- Airless EV tyres

- Sensor-embedded smart tyres

- Sustainable rubber compounds

Conclusion

The EV revolution is more than batteries and charging infrastructure — it depends on the tyres that connect vehicles to the road. EV-specific tyres are the foundation of performance, safety, and efficiency in tomorrow’s mobility.

At Trojan | The Global Tyre Company, we help importers, fleets and distributors worldwide source EV-specific tyres directly from verified manufacturers. With our expertise in global sourcing, technical support and logistics, we ensure your business is equipped for the EV era.

👉 Get in touch with our team today to explore premium EV tyre solutions for your market.